- Manufacture

- machining

- grinding

- Section 1

Yoshinaga/Sakamoto

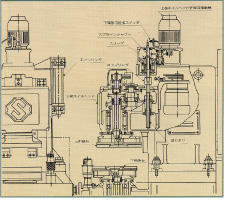

"Parallel-Surface Honing and Grinding Machine" which

we are manufacturing has original technology.

This machines have obtained high evaluation to the customer

in the world including Japan.

- Time shortening by simultaneous both side grinding

This machine is possible to grind simultaneously both side of upper and bottom of some work-pieces by the two circular grinding wheels of top and bottom, and be short processing time.

This machine is possible to grind simultaneously both side of upper and bottom of some work-pieces by the two circular grinding wheels of top and bottom, and be short processing time.- Grinding of non-magnetic substance work-pieces

- This machine have planetary gear system, be not a magnetic table. It is able to process there easily by carrier (holder) system without any distinction of the magnetic substance (iron, ferrite etc.), non-magnetic substance (copper, aluminum, ceramic, glass etc.). Loading and unloading is easy, and operation efficiency is good.

- Parallelism and Flatness of high precision

This machine is possible to gain parallelism, flatness and surface finish of high precision by "honing action" and "planetary gear action". " honing action" is the complex action of revolution and reciprocating motion of grinding wheels. " Planetary gear action" is the around and rotate trip of work-pieces in planetary gear system.

This machine is possible to gain parallelism, flatness and surface finish of high precision by "honing action" and "planetary gear action". " honing action" is the complex action of revolution and reciprocating motion of grinding wheels. " Planetary gear action" is the around and rotate trip of work-pieces in planetary gear system.- Few cracked or broken of work-pieces

It is the constant-pressure grinding system by air pressure, not using to send a compulsion screw. There are no worries about crack and broken of work-pieces of glass, ferrite and ceramic. Grinding pressure is controlled by adjustment a pressure of air cylinder.

It is the constant-pressure grinding system by air pressure, not using to send a compulsion screw. There are no worries about crack and broken of work-pieces of glass, ferrite and ceramic. Grinding pressure is controlled by adjustment a pressure of air cylinder.